Diesel Lift Pumps: What is More Important, Pressure or Flow?

There seems to be a lot of confusion on this subject. You must have adequate flow to support the needs of the engine. What about pressure? Is pressure just a product caused by the resistance to flow? Is pressure necessary? Does a drop in pressure at wide open throttle mean I don’t have enough flow?

Sizing a lift pump with adequate flow is the first step. You need enough flow to support the type of injection system you are running. Sizing by horsepower will get you in the ballpark, but ultimately your injection system has to be taken into consideration. Going off horsepower alone is not enough information. Pressure exists due to a resistance in flow. When it is put that way, it sounds like a bad thing. However, pressure is necessary for a fuel system.

Many fuel injection pumps rely on fuel pressure to operate the timing circuit. All fuel systems benefit from pressure during high demand situations. A diesel engine running at 3000 RPM has very little time to fill a pumping element before the next cycle…milliseconds, literally. Pressure helps to fill the pumping element. If pressure drops too far, the pumping element will pull a vacuum. It will live with some vacuum, but too much will cause cavitation and vaporization. This condition can cause more damage than dirty fuel. In layman’s terms, cavitation causes the fuel to vaporize. The vapor fills the pump cavity; then the pump pressurizes the vapor. When the vapor is compressed, it implodes. The implosion erodes the metal away and leaves craters in the surface.

A quality fuel pressure gauge at the inlet of the injection pump should be used in all high performance applications. This is a cheap and simple way to monitor fuel system needs. What causes pressure drop at WOT? The first thing that usually comes to mind is the lift pump won’t keep up. That, however, is usually the incorrect answer. Many things can cause low pressure.

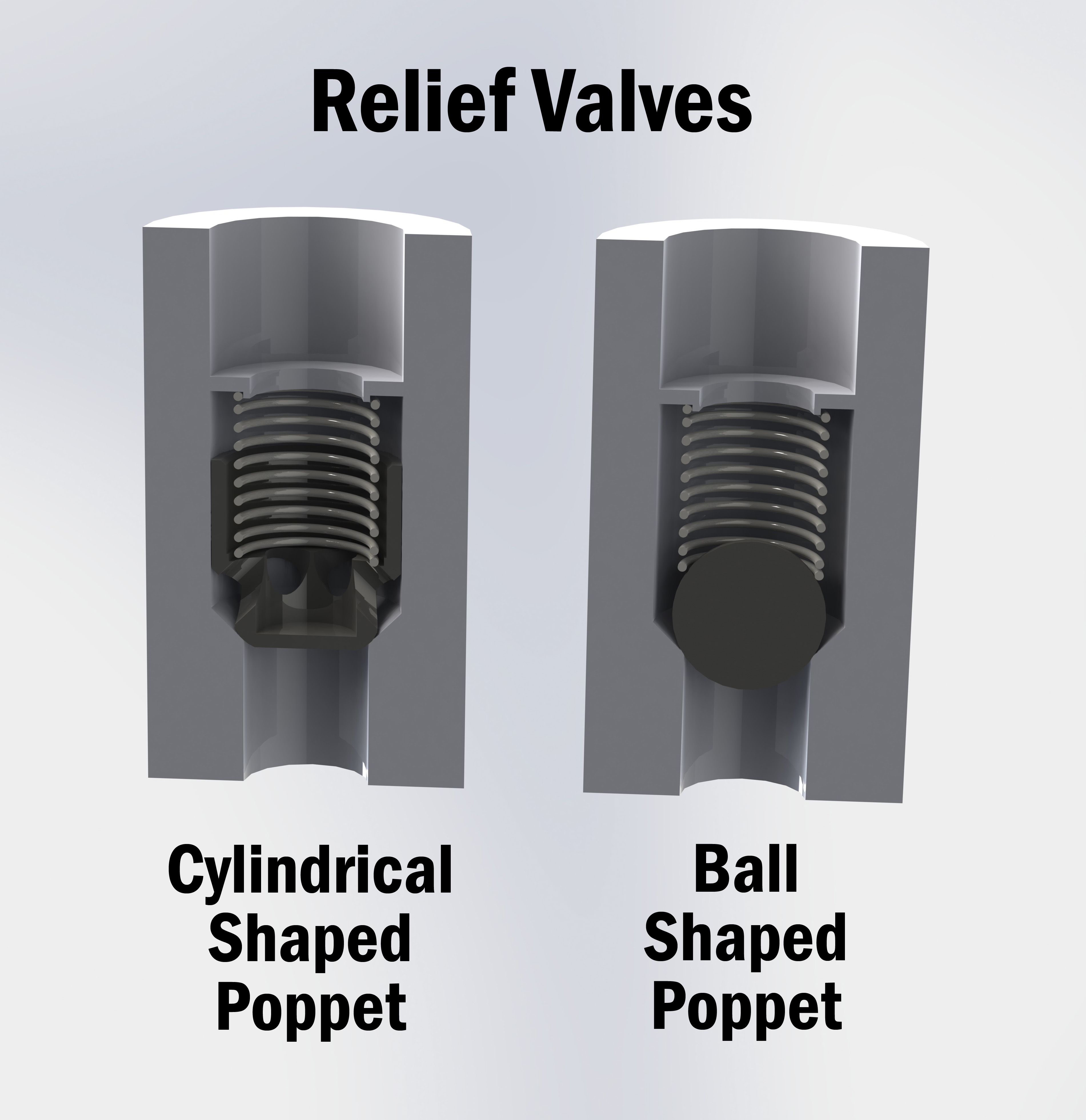

The fuel pressure relief valve (what regulates the pressure) is one that is often overlooked. Not all relief valves are the same. Even if they look identical, there can be minor differences that have a major impact on valve performance. Spring selection is one common mistake with budget relief valves. There is no “one size fits all” in this category. You cannot take an 8 PSI relief valve and simply shim the spring to 18 PSI. It can be set to run at 18 PSI, but it will be erratic and drop off in pressure, under wide open throttle.

A quality relief valve will run steady pressure at idle and maintain that pressure at cruising speeds. A full throttle run should have a minimal amount of pressure drop. It should be noted that fuel pressure relief valve poppet design can have a major impact on fuel pressure and flow.

The Ball Shaped Poppet is commonly used, however, this is a flawed design as the ball can vibrate (also known as “valve chatter”), which inhibits smooth fuel flow and creates fuel pressure spikes.

A Cylindrical Shaped Poppet provides a superior design, as the diameter of the upper portion of the poppet is stabilized within the bore of the valve housing. The poppet smoothly slides open and closed along the bore. This combined with the inlet ports on the side of the poppet smooths fuel flow, and valve chatter is virtually eliminated. This reduces fuel pressure spikes and results in a much better fuel flow curve.

Pressure versus flow, they are both important. While flow is a necessity, pressure with good regulation is vital to a quality fuel system.

Written by Matt Gilmore

You must login to post comments.