- Home »

- FAQ

Fuelab FAQ

- Privacy Policy

- Shipping

- FAQ

- Where is the Best Place to Use a Check Valve?

- Where is the best place to mount my Surge Tank?

- What size lift pump should I use?

- What size inlets are on Fuelab Regulators?

- What size Fuel Pump should I use?

- What Micron rating should I use?

- What is the Warranty on Fuelab Fuel Pumps?

- What is the service interval of my Fuel Filter?

- What is the advantage of using a Surge Tank over multiple in-tank pumps?

- What fuel types are Fuelab Fuel Filters good for?

- What Are The Common Types of Fittings

- Understanding Fuel Line Fittings: Straight Thread (and AN) vs. Tapered Thread?

- Loose Wires?

- How do I know if I need to upgrade my OEM Fuel Pressure Regulator?

- How do I know if I need a Surge tank?

- How big of a Fuel Filter do I need?

- How and Why should I Winterize?

- Do I need to use a Check Valve in my Fuel System?

- Do I need to Pre Filter my fuel pump?

- Do I need a bypass or blocking style Fuel Pressure Regulator?

- Do Fuelab Regulators come with Fittings?

- Do Fuelab Regulators come with a Gauge?

- Do Fuelab Fuel Filters come with fittings?

- Can I use a Surge Tank as a Fuel Cell?

- Can I mount my Fuel Pressure Regulator Upside Down?

- Can I clean my filter element?

- Are Fuelab Regulators compatible with boosted setups?

- Are Fuelab Fuel Pumps PWM (Pulse-Width Modulation) compatible?

- Are Fuelab Fuel Pumps Ethanol Compatible?

- Looking for Troubleshooting guide?

- Troubleshooting

- Speed of Fuel Pump changes up and down very noticeably and erratically

- Loss of fuel pressure or erratic pressure pulsation after several minutes of Fuel Pump operation

- Leakage of fuel at inlet or outlet fuel ports in Fuel Pump

- Leakage of fuel at inlet and outlet ports

- Leakage of fuel at filter body and inlet/outlet

- Fuel Pump with internal controller not operating or slight "clicking" sound when turned on

- Fuel Pump with external controller is not operating or "clicking" sound when turned on

- Fuel Pump not building fuel pressure

- Fuel Pump is operating in a reverse flow direction

- Fuel Pressure Regulator does not hold pressure after engine is shut off

- Fuel Pressure Regulator does not build pressure

- Fuel Pressure is unstable

- Fuel pressure drops off under heavy engine load

- Fuel Pressure Drop

- Looking for answers to Frequently Asked Questions?

- Where is the Best Place to Use a Check Valve?

- Where is the best place to mount my Surge Tank?

- What size lift pump should I use?

- What size inlets are on Fuelab Regulators?

- What size Fuel Pump should I use?

- What Micron rating should I use?

- What is the Warranty on Fuelab Fuel Pumps?

- What is the service interval of my Fuel Filter?

- What is the advantage of using a Surge Tank over multiple in-tank pumps?

- What fuel types are Fuelab Fuel Filters good for?

- What Are The Common Types of Fittings

- Understanding Fuel Line Fittings: Straight Thread (and AN) vs. Tapered Thread?

- Loose Wires?

- How do I know if I need to upgrade my OEM Fuel Pressure Regulator?

- How do I know if I need a Surge tank?

- How big of a Fuel Filter do I need?

- How and Why should I Winterize?

- Do I need to use a Check Valve in my Fuel System?

- Do I need to Pre Filter my fuel pump?

- Do I need a bypass or blocking style Fuel Pressure Regulator?

- Do Fuelab Regulators come with Fittings?

- Do Fuelab Regulators come with a Gauge?

- Do Fuelab Fuel Filters come with fittings?

- Can I use a Surge Tank as a Fuel Cell?

- Can I mount my Fuel Pressure Regulator Upside Down?

- Can I clean my filter element?

- Are Fuelab Regulators compatible with boosted setups?

- Are Fuelab Fuel Pumps PWM (Pulse-Width Modulation) compatible?

- Are Fuelab Fuel Pumps Ethanol Compatible?

- Looking for Troubleshooting guide?

- Speed of Fuel Pump changes up and down very noticeably and erratically

- Loss of fuel pressure or erratic pressure pulsation after several minutes of Fuel Pump operation

- Leakage of fuel at inlet or outlet fuel ports in Fuel Pump

- Leakage of fuel at inlet and outlet ports

- Leakage of fuel at filter body and inlet/outlet

- Fuel Pump with internal controller not operating or slight "clicking" sound when turned on

- Fuel Pump with external controller is not operating or "clicking" sound when turned on

- Fuel Pump not building fuel pressure

- Fuel Pump is operating in a reverse flow direction

- Fuel Pressure Regulator does not hold pressure after engine is shut off

- Fuel Pressure Regulator does not build pressure

- Fuel Pressure is unstable

- Fuel pressure drops off under heavy engine load

- Fuel Pressure Drop

- Looking for answers to Frequently Asked Questions?

Privacy Policy

Q: I. WHAT THIS PRIVACY POLICY COVERS

This policy covers how FUELAB treats personal information that it collects and receives. “Personal information” is information like your name, address, email address, or phone number that is not otherwise publicly available.

This policy does not apply to the practices of companies that FUELAB does not own or control or to people that FUELAB does not employ or manage.

Q: II. INFORMATION COLLECTION AND USE

A. General

FUELAB gathers personally identifiable information about users of the Site through the registration process and other means, such as user submissions and any web sites accessible through our Site. We use this personal information primarily to provide a customized experience as you use our Site and, generally, do not share this information with third parties except as set forth herein. However, we may disclose personal information collected if we have received your permission beforehand or in very special circumstances, such as when we believe that such disclosure is required by law or other special cases described below.

B. Personal Information

1. Registration: When you register to receive information or products from the Site, you will be asked to provide certain personal information when you sign up including name, address, telephone number, payment information, and email address. The personal information collected from Members during the registration process is used to manage each Member’s account (such as for billing purposes). This information is not shared with third parties, unless specifically stated otherwise or in special circumstances. However, in instances where FUELAB and a partner jointly promote the Site, FUELAB may provide the partner certain personal information, such as the name, address, and username of persons who subscribed to the Site or as a result of the joint promotion for the sole purpose of allowing us and the partner to assess the results of the promotion. In this instance, personal information may not be used by the partner for any other purpose. FUELAB may also generate non-identifying and aggregate profiles from personal information Members provide during registration (such as the total number, but not the names, of Members). As explained in more detail below, we may use this aggregated and non-identifying information to sell advertisements that appear on the Site.

2. Online Shopping: On the Site, you can purchase products, services or register to receive materials, such as a catalog or new product and service updates. In many cases, whether Member or non-registered user of the Site (“Visitor”), you may be asked to provide contact information, such as your name, address, email address, phone number, and credit/debit card information. If you complete an order for someone else, such as an online gift order sent directly to a recipient, you may be asked to provide information about the recipient, such as the recipient’s name, address, and phone number. FUELAB has no control over the “third parties” use of any personal information you provide when placing such an order. Please exercise care when doing so.

If you order products directly from FUELAB, we will use the personal information you provide only to process that order. We do not share this information with outside parties except to the extent necessary to complete that order.

3. Online Advertisements: FUELAB displays our online advertisements. We share aggregated and non-identifying information about our Visitors and Members collected through the registration process as well as through online surveys and promotions with these advertisers. Additionally, in some instances, we use this aggregated and non-identifying information to deliver tailored advertisements. For instance, an advertiser tells us the audience they want to reach (for example, females between 25 and 35 years of age) and provides us an advertisement tailored to the audience. Based upon the aggregated and non-identifying information we have collected, we may then display the advertisement to the intended audience. FUELAB does not share personal information about its Visitors or Members with these advertisers.

4. Responses to Email Inquiries: When Visitors or Members send email inquiries to FUELAB, the return email address is used to answer the email inquiry we receive. FUELAB does not use the return email address for any other purpose and does not share the return email address with any third party.

5. Special Cases: It is FUELAB’s policy not to use or share the personal information about Visitors of Members in ways unrelated to the ones described above without also providing you an opportunity to opt out or otherwise prohibit such unrelated uses. However, FUELAB may disclose personal information about Visitors or Members, or information regarding your use of the Site or Web sites accessible through our Site, for any reason if, in our sole discretion, we believe that it is reasonable to do so, including: to satisfy laws, such as the Electronic Communications Privacy Act, regulations, or governmental or legal requests for such information; to disclose information that is necessary to identify, contact, or bring legal action against someone who may be violating our Terms & Conditions or other user policies; to operate the Site properly; or to protect FUELAB and our Members.

C. Non-Personal Information & Cookies

FUELAB also gathers non-personal information through standard tracking mechanisms on FUELAB internet servers. For example, FUELAB employs “cookies” on various parts of the Site. Cookies are information that the Site transfers to the user's hard drive to facilitate record keeping and tracking a user's preferences. Non-personal information is primarily collected in order to improve the functionality and user's enjoyment of the Site, to tailor the Site to your individual preferences, and to make using the Site simpler and more enjoyable. The information that is typically tracked includes the type of internet browser and operating system being used by a user, and the user’s internet service provider.

D. Security

The importance of security for all personally identifiable information associated with users is of the utmost concern to FUELAB. Unfortunately no data transmission over the internet can be guaranteed to be 100% secure. As a result, while FUELAB strives to protect users’ personal information, FUELAB cannot ensure or warrant the security of any information users transmit to the Site, and users do so at their own risk.

Your account information is protected by the password you use to access your online account. If you use this Site, you are responsible for maintaining the confidentiality of your account and password and for restricting access to your computer, and you agree to accept responsibility for all activities that occur under your account or password.

Personal information that is maintained in our offices or stores is subject to physical, administrative, and technical controls as well. Hard copies of private information are maintained in locked locations or cabinets with similar restrictions for electronic storage of private information. When disposed of, the information is shredded, destroyed, erased, or otherwise made unreadable.

Q: III. COMMITMENT TO CHILDREN'S PRIVACY

Protecting children’s privacy is especially important to us. It is our policy to not knowingly solicit or exchange information with children under the age of 13 or otherwise contact children for any purpose. While we make every effort to ensure that the Site is fun and age-appropriate for our younger audience, we believe that there is no substitute for proper parental supervision. For further information about tips, tools, age-appropriate or kid-friendly Web sites and how to report online trouble, please visit www.getnetwise.com.

It is our policy to comply with the Children’s Online Privacy Protection Act of 1998 and all other applicable laws. Therefore, children under the age of 13 are not permitted to register for the Site. Children under 13 may use the Site, but should do so only with parental supervision, especially when it relates to the disclosure of personal information about children. Although FUELAB will do what it can to screen information from children under the age of 13 on the Site, FUELAB has no way to guarantee that a registrant or user is under 13. Therefore, to the maximum extent permitted by law, FUELAB is not responsible for a child’s use of the Site or the personal information supplied by a child on the Site.

Q: IV. USER-INITIATED COMMUNICATION

From time to time, portions of the Site may enable you to send email to us or to third parties and to participate in public bulletin boards and discussion groups (hosted by us or one or more of our service providers). All postings to public bulletin boards and discussion groups become our property. Whenever you choose to initiate these kinds of communications with us, or anyone else, you may expect to be contacted in return.

Also, remember that our bulletin boards and discussion groups are open to the public, and therefore, your postings can be seen by anyone and are not protected by us or any other entity. Please use your own discretion when deciding what to post publicly, and whom to contact. We reserve the right, in our sole discretion, to edit or delete inappropriate postings from our bulletin boards and discussion groups; provided, however, the reservation of this right shall not, under any circumstances, obligate us to conduct such editing or deletions.

Q: V. THIRD PARTY LINKS

This Privacy Policy only applies to this Site. The Site contains links to web sites that are not operated or controlled by FUELAB, when you click on one of those links, you are entering another web site. Please be aware that these sites may collect information about you, and operate according to their own privacy practices that may differ from this Privacy Policy. The placement of links on the Site does not imply that FUELAB endorses or warrants the content on any third party web site. Please remember to read the terms of use and privacy policies for those sites, as they may differ from these terms of use. Remember that once you're outside the Site, any information you submit is outside of our control.

Q: VI. TERMS AND CONDITIONS

For an explanation of FUELAB’s practices and policies related to the Sites terms and conditions of use, please read our Terms and Conditions.

Q: VII. REVISIONS TO THIS POLICY

FUELAB reserves the right to revise, amend, or modify this policy, its Terms and Conditions and our other policies and agreements at any time, and in any manner. Notice of any revision, amendment, or modification will be posted in accordance with the Terms and Conditions. Accordingly, we encourage you to periodically review this Privacy Policy and the Site in order to keep apprised of our current privacy practices. If you do not agree to any provision of this Privacy Policy, or any update or modification thereto, please do not use the Site.

Q: VIII. WHERE TO DIRECT QUESTIONS ABOUT THE FUELAB PRIVACY POLICY

1605 Eastport Plaza Drive Suite 125

Collinsville, IL 62234 USA

Effective date: November 30, 2020

Shipping

Q: What time should the order be placed to be processed on the same day?

Orders must be placed before 3 pm CST for an order to be processed on the same day.

If you need an item by a specific date, please place the order on this website then call 618-344-3300 to confirm that we will be able to meet your requirements.

Q: What are the Shipping Charges?

We use real time shipping rates based on total order weight, destination and service.

Q: What are the FedEx US Domestic Estimated Transit Times?

Customers may authorize expedited shipments for an additional charge. Open or concealed freight damage claims must be made to the freight carrier. Damaged merchandise should not be returned to FUELAB unless prior authorization has been obtained.

FAQ

Q: Where is the Best Place to Use a Check Valve?

A check valve can have many functions: hold rail pressure, shorten the pump priming time, and help with hot starts. Emissions are more important than ever these days as well. Holding rail pressure while the engine is cooling, prevents the fuel from boiling off, thus cutting back on evaporative emissions. The EPA is all over the motorsports industry these days, so its up to all of us to do our part.

Q: Where is the best place to mount my Surge Tank?

Q: What size lift pump should I use?

Q: What size inlets are on Fuelab Regulators?

Q: What size Fuel Pump should I use?

Fuel pump size requirements depend on Fuel Pressure, Fuel Type, and Induction type. We recommend that you refer to our Fuel Pump Calculator and input your desired power rating and setup to best decide your flow needs.

Q: What Micron rating should I use?

Q: What is the Warranty on Fuelab Fuel Pumps?

Q: What is the service interval of my Fuel Filter?

Q: What is the advantage of using a Surge Tank over multiple in-tank pumps?

Q: What fuel types are Fuelab Fuel Filters good for?

Q: What Are The Common Types of Fittings

Adapter Fittings – also known as Standard Fittings or Union Fittings – are commonly used to connect fuel line tubes and hoses to fuel pumps, fuel regulators, and fuel filters. While Adapter Fittings are available in SAE size configurations, most high-end racing and performance fuel systems use those manufactured to AN standards (document AN815, defines standard union fittings). With AN versions, the fitting ends typically use a 37° cone on each end (as per Military Standard MS33656). AN standards dictate use of Straight Thread for Adapters, requiring use of O-rings. Special port machining is done to "capture" and properly compress the O-ring, as too much stress can damage the O-ring, and too little can cause leakage. These port standards are designed to precisely "load" the O-ring automatically during installation. Use of The O-ring seals allow for greater sealing ability with very high reliability of installation as compared to Tapered Thread using sealing compounds or Teflon tape.

Pipe Fittings - Pipe Fittings can be used to connect fuel lines to the port on a fuel pump or fuel pressure regulator, as well as connect fuel pressure gauges to gauge ports. One end (the port end) of the fitting can be described as a male open-ended cylinder with Tapered Thread (also called Pipe Thread) on the outer diameter. This fits into a female port of corresponding size and thread pitch. The other end typically uses a 37° cone and Straight Thread. The Tapered Thread on the port end of the fitting must use sealing compound or Teflon tape to help avoid leakage. However, in high-pressure fuel system applications this method has proven more leak prone than the O-ring seal method used with Straight Thread fittings. As well, Teflon tape has the potential to leave debris in the fuel systemWhich leads us to the description of Port Fittings.

Port Fittings - Port Fittings (also known as O-Ring Base or ORB fittings) function just like Pipe Fittings, but with the following distinctions. Port Fittings conform to AN standards - typically per Military Standard MS33649. The cone end uses Straight Thread and a 37° cone. The male port end of the fitting uses Straight Thread, and is received by a female port of corresponding size and thread pitch. Port Fittings require use of O-rings. Like AN Adapters, special port machining is done to "capture" and properly compress the O-ring which allows for greater sealing ability with very high reliability of installation as compared to Tapered Threads using sealing compounds or Teflon tape. This reliability makes Port Fittings the preferred choice over Pipe Fittings for high-end racing and performance fuel system applications. It should be noted that while manufacturers of high performance fuel delivery systems often specify Port Fittings for connections to fuel pumps and fuel pump regulators, the connections to fuel pressure gauges, via gauge ports, most often utilize Pipe Fittings. This is because the vast majority of the in-line fuel pressure gauges on the market use Pipe Fittings for connection.

We hope this overview has provided a better understanding of the differences and uses of Straight Thread versus Pipe Thread, as well as the types of fittings used. If you have further questions about fuel delivery system plumbing, please contact Fuelab Technical Support.

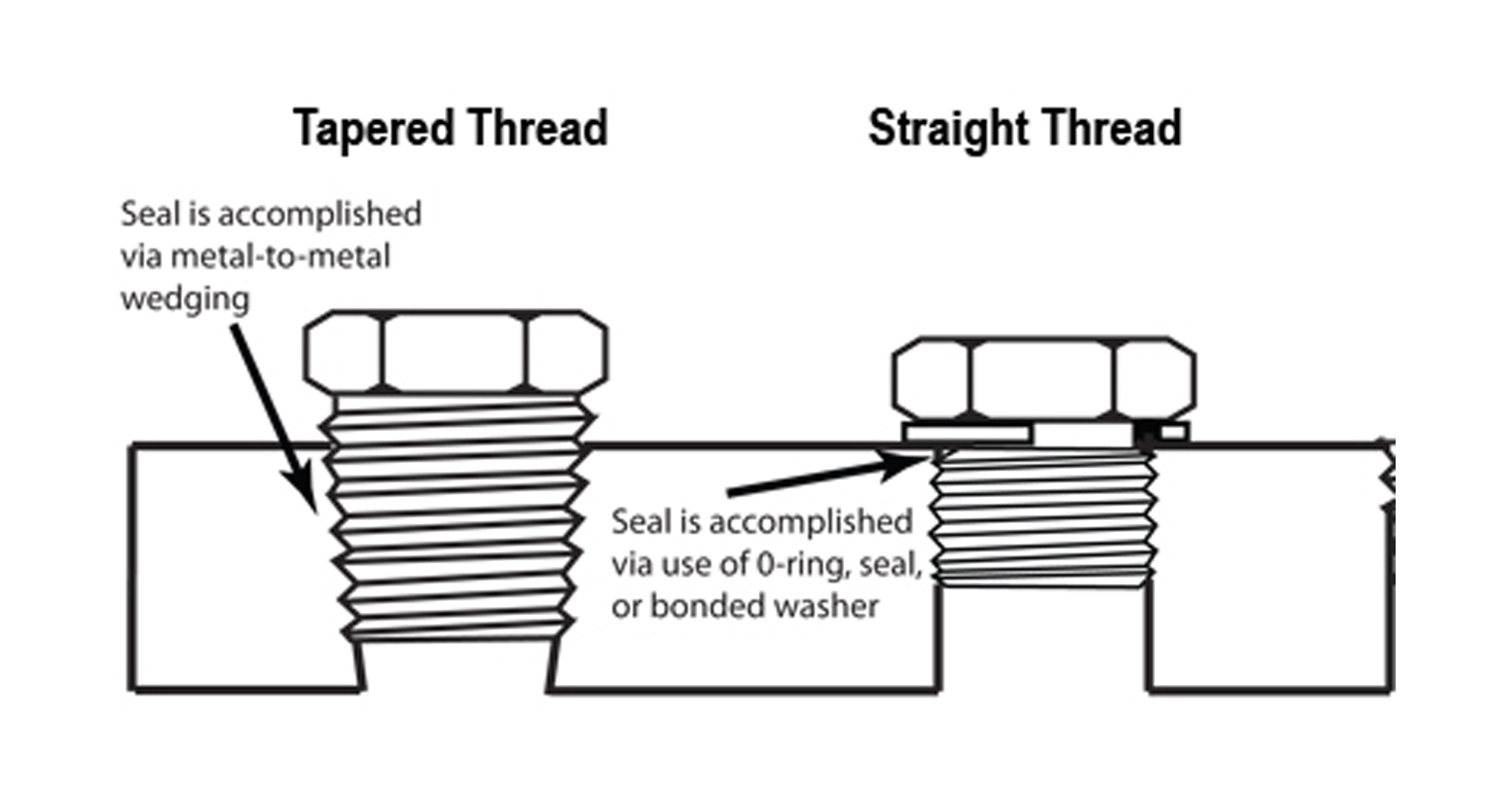

Q: Understanding Fuel Line Fittings: Straight Thread (and AN) vs. Tapered Thread?

Before we get into the types of fittings we’ll first define the thread types used on the fittings, as well as discuss applicable AN standards.

Thread Types:

Straight Thread - With straight thread the threads run parallel. Port Fittings and Adapter fittings using straight thread require use of an O-ring Boss Seal technique to seal against leakage. NPSC - American Standard Straight Coupling Pipe Thread are the standards for Straight Thread in the US.

Tapered Thread – Tapered thread, also known as Pipe Thread, typically uses a 2° angle on the threads (instead of running parallel). This allows the threads to interfere and seal off. Threads must be clean and precise, to make up for gaps between threads that allow for leakage. Pipe Fittings, which use Tapered Thread, don’t use O-rings, but rather must use compounds or Teflon Tape to help seal the threads. National Pipe Thread Taper (NPT) is a U.S. standard for tapered threads used on threaded pipes and fittings.

AN Standards - High-end racing and performance fuel delivery systems most frequently implement fuel lines and fittings manufactured to AN Standards. During WWII the US military set specification standards for fasteners and fluid fittings used on military equipment. These standards are headed under “AN” which is the abbreviation for “Army-Navy", but is also known as "Air Force - Navy Aeronautical Standard". After the war many used surplus aerospace parts were used for racing, and thus introduced the AN standard into the racing and performance world. AN Standards as Applied to Fluid Carrying Tubes and Flexible Hoses In the case of tubes and flexible hoses used to carry fluid, “AN Size” designates the outer diameter of the hose or tubing in 1/16” increments. For example an AN size 2 designates a tube OD of 1/8” (2 x 1/16”), the tube OD of AN size 3 is 3/16” (3 x 1/16”). Note: The AN size number is correctly displayed with a dash before the number.

- FYI: Popular fuel line sizes:

- -6AN (=3/8" OD)

- -8AN (=1/2" OD)

- -10AN (=5/8" OD)

- -12AN (=3/4" OD)

- Use of -3AN and -4AN line:

- Typically, these 1/4" and 5/16" line sizes are in use for low flow or OEM systems, but are commonly used in high performance applications for pressure gauges as well as plumbing between the Regulator and Intake Manifold. These two lines do not involve significant amounts of flow, and therefore do not require larger sizes.

- Typically, the port sizes used with these smaller sizes use a 1/8"- NPT. 1/8"-NPT fittings are very common and can easily be used to adapt to -3AN or -4AN line.

AN Standards as Applied to Fluid Carrying Fittings Each AN size also references a standard male and female thread size that is used on fittings - such as hose end fittings, adapters, and port fittings. This is known as “AN Thread Size”. AN fittings have Straight Thread, and use O-ring seals. The O-ring size is typically defined by the "AS" standard. Dash Numbers are typically assigned based on the size. Boss-Seal style O-rings are typically in the "900" Series. For example -906 is for -6AN ports, and -908 is for -8AN ports. AN Size and AN Thread Size Reference Chart The chart below references the tube (or flexible hose) OD and thread size for each AN size.

AN SizeTube or Hose ODTube or Hose IDFitting Thread Size(SAE) - 21/8”.062”5/16-24-33/16”.125”3/8-24-4¼”.172”7/16-20-55/16”.062”1/2-20-63/8”.297”9/16-18-81/2”.391”3/4-16-105/8”.484”7/8-14-12¾”.609”1-1/16-12-161”.844”1-5/16-12-201 ¼”1.078”1-5/8-12-241 ½”1.312”1-7/8-12-281 ¾”1.547”2-1/4-12-322”1.781”2-1/2-12

*Note: While these measurement s reflect AN standards, actual ID and OD can vary slightly from AN specification depending on supplier. BE SURE TO USE COMPATIBLE FITTINGS ONLY! Mismatched lines can come apart under pressure. Verify that inner diameters match!

Q: Loose Wires?

If you’re having problems with anything electrical, take the simple steps below along with a simple visual check before assuming your ________ (insert random part name here) has failed. In many cases, simply jiggling some wires is all the troubleshooting you’ll need to do in order to find the problem – no fancy meter or tedious steps required!

Often I get a tech call from someone that suspects they have a pump failure. One of my first questions is whether or not they’ve checked their wiring. I almost always get some version of “Yeah, it looks fine!”. There’s more to wiring than just how it looks, and I experienced that firsthand as I found myself on the side of the road last Friday morning with a suspected pump failure. Granted, this was with an OEM pump on an S10 that has experienced 23 years’ worth of Midwest rain and road salt, but it still serves as a good example to my point. At first glance, the shared ground for the fuel pump and rear signal light looked OK – light corrosion/rust but nothing outside the norm for a daily driver, the ground bolt was tight, the ring terminal was in good shape and the crimp was still tight. It seems over the years, the wire finally broke inside the insulation. From the outside everything looked fine, but it wasn’t until the wire was moved that the problem presented itself. Simply cutting the wire and installing a new ring terminal got me back in action….after a 3mi walk home and a tow bill. I’d have been awfully frustrated had I went through the expense and hassle of installing a new pump, only to have the same issues I had previously. More times than not, the fix is something simple – don’t just “check” the basics, actually CHECK them.

Q: How do I know if I need to upgrade my OEM Fuel Pressure Regulator?

Q: How do I know if I need a Surge tank?

Q: How big of a Fuel Filter do I need?

Q: How and Why should I Winterize?

Winter is fast approaching. That means it’s time to remove the summer air from your tires, fill them with winter air, and do a little fuel system winterization on the race car!

Contrary to popular belief, your car’s fuel tank is not a long-term fuel storage vessel. For those of you that just run pump gas, this is as easy and draining the fuel out or just dumping a little Sta-bil (or equivalent) in the tank.

For those of you that are running a something a bit more spicy than pump gas, the process is just a little more involved, but not much.

Start with draining the good stuff. After that, cycle the system with pump gas (bonus points if you add some Sta-bil or similar) to flush the pump, filters, lines, and the carb or EFI bits that are downstream. Some folks will even go the extra mile and remove the pump completely after flushing and spray lube (WD-40, light oil, 2-stroke oil, top end lube, etc.) down the inlet of the pump and manually spin it by hand a bit to work it around.

Whatever you do, don’t do what this guy did, which was nothing at all. A few minutes of post-season prep work will save you a ton of headaches, time, and money come that first spring day when it’s time to dust off your car and blow the winter cobwebs out.

Q: Do I need to use a Check Valve in my Fuel System?

Q: Do I need to Pre Filter my fuel pump?

Q: Do I need a bypass or blocking style Fuel Pressure Regulator?

Q: Do Fuelab Regulators come with Fittings?

Q: Do Fuelab Regulators come with a Gauge?

Q: Do Fuelab Fuel Filters come with fittings?

Q: Can I use a Surge Tank as a Fuel Cell?

Q: Can I mount my Fuel Pressure Regulator Upside Down?

Q: Can I clean my filter element?

Q: Are Fuelab Regulators compatible with boosted setups?

Q: Are Fuelab Fuel Pumps PWM (Pulse-Width Modulation) compatible?

Q: Looking for Troubleshooting guide?

Check out Troubleshooting page for details

Troubleshooting

Q: Speed of Fuel Pump changes up and down very noticeably and erratically

Possible Causes:

If your Fuel Pump is changing speed and acting erratically, your issue could be a loose terminal or a failed circuit in your Fuel Pump wiring.

Possible Solutions:

Check the voltage to your fuel pump at the power terminals. If the voltage is steady and consistent (within ½ Volt of battery) then contact Fuelab for repair. If voltage is inconsistent as described, repair or replace the electrical components as needed.

Q: Loss of fuel pressure or erratic pressure pulsation after several minutes of Fuel Pump operation

Possible Causes:

One possible and most common issue of fuel pressure loss or erratic fuel pressure pulsation is often cavitation or otherwise known as vapor lock, due to overheating or restricted inlet.

Possible Solutions:

Check the temperature of pump right after failure. If pump is hot to touch (cannot leave hand on pump due to it being too hot, or above 120°F), then look for sources of heat such as exhaust or fuel rail mountings that could be conducting too much heat. If pump is not hot to the touch, check for inlet restrictions such as improperly vented tank, kinks in the fuel line, or too small of plumbing for application. Contact Fuelab, as pump may be damaged due to improper operating condition for repair or consultation. Consider speed control scheme to allow pump to operate at reduced speeds during long periods of operation under low demand. Contact Fuelab for more details.

Q: Leakage of fuel at inlet or outlet fuel ports in Fuel Pump

Possible Causes:

Improper type of fitting used for fuel system.

Possible Solutions:

Q: Leakage of fuel at inlet and outlet ports

Possible Causes:

Damage to 37 degree flare of male fitting ends.

Possible Solutions:

Inspect for damage and replace if necessary.

Q: Leakage of fuel at filter body and inlet/outlet

Possible Causes:

Loose assembly of inlet/outlet to body. Damaged o-ring.

Possible Solutions:

Make sure that inlet and outlet are tightened to between 13-17 Ft/lbs. Inspect o-rings for any possible damage. Replace as needed.

Q: Fuel Pump with internal controller not operating or slight "clicking" sound when turned on

Possible Causes:

Faulty fuel pump relay. Faulty, dirty, or corroded terminals or improperly sized wire. Debris from tank or plumbing lodged inside pump.

Possible Solutions:

Q: Fuel Pump with external controller is not operating or "clicking" sound when turned on

Possible Causes:

If your Fuel Pump that is controlled by an external controller is not operating correctly or is making a clicking sound, your issue could be poor wiring quality or poor connections between pump and controller (motor phase wiring) or a warranty issue with the pump.

Possible Solutions:

Check all motor phase wiring connections. DC Brushless Fuel Pump wiring is especially sensitive to resistance. Please contact Fuelab for any issues with warranties on your Fuelab Fuel Pump.

Q: Fuel Pump not building fuel pressure

Possible Causes:

The possible issue with your fuel pump not building fuel pressure can be due to an incorrect fuel system initial priming procedure.

Possible Solutions:

Q: Fuel Pump is operating in a reverse flow direction

Possible Causes:

The possible issue for your Fuel Pump operating in a reverse flow direction is improper motor phase wiring order.

Possible Solutions:

Swap two of the three motor phase wires with each other (leave the third wire connected). Any two of the three wires can be swapped, color does not matter.

Q: Fuel Pressure Regulator does not hold pressure after engine is shut off

Possible Causes:

A potential issue in this case could be a lack of check valve to prevent flow back thru the pump and into the tank or poor seating of regulator diaphragm.

Possible Solutions:

Verify that the fuel pump has a check valve. If not, we recommend and external check valve to hold line pressure. If bleed down continues, contact FUELAB for further assistance.

Q: Fuel Pressure Regulator does not build pressure

Possible Causes:

Fuel Pressure Regulator plumbed incorrectly. Faulty fuel pump. Faulty pressure gauge.

Possible Solutions:

Verify that the Fuel Pressure Regulator is plumbed properly. Bypass style and blocking style have opposite inlet/outlet configurations. Verify that the fuel pump is able to build enough flow to open diaphragm or poppet assembly. Verify fuel pressure gauge is in working order.

Q: Fuel Pressure is unstable

Possible Causes:

Air induction into fuel, faulty fuel pump.

Possible Solutions:

Check for loose fittings at all points in the system. Ensure the return line to the tank is not splash filling into the inlet area of the fuel pump. Use an extension from the top of the fuel cell or fuel tank to approximately 1/2" from bottom, being careful to not restrict return line. Verify pump is in working order.

Q: Fuel pressure drops off under heavy engine load

Possible Causes:

Fuel pressure drop can be caused by incorrect wiring of your Fuelab speed control, a loose terminal or wiring or insufficient fuel capacity.

Possible Solutions:

To fix your fuel pressure drop, make sure that your fuel pump is operating at full speed while under high engine load. Check your voltage to fuel pump and at the power terminals. If your fuel pump voltage is steady and consistent (within ½ Volt of battery) then contact Fuelab for support. If your fuel pump voltage is inconsistent as described, you will want to repair or replace some electrical components as required. If condition continues, an upgraded pump capacity may be required. Please contact Fuelab for any further questions!

Q: Fuel Pressure Drop

Possible Causes:

Dirty Filters!

Possible Solutions:

Replace filters as needed. Inspect at least annually for debris. Changes in fuel pump pitch may indicate restrictions that require immediate attention.

Q: Looking for answers to Frequently Asked Questions?

Check out FAQ page for details